From first prototypes to serial production

In the group of companies MegaPlast GmbH & MegaPrototyping GmbH & Co. KG, which are located together at Steinbach-Hallenberg, we are offering to our customers continuous manufacturing processes - from product development to series production.

"All from a single source!"

Our group of companies

MegaPlast GmbH

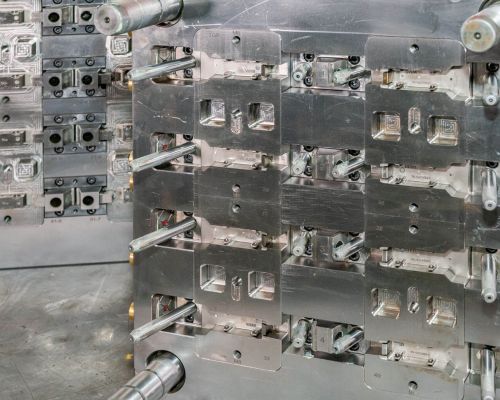

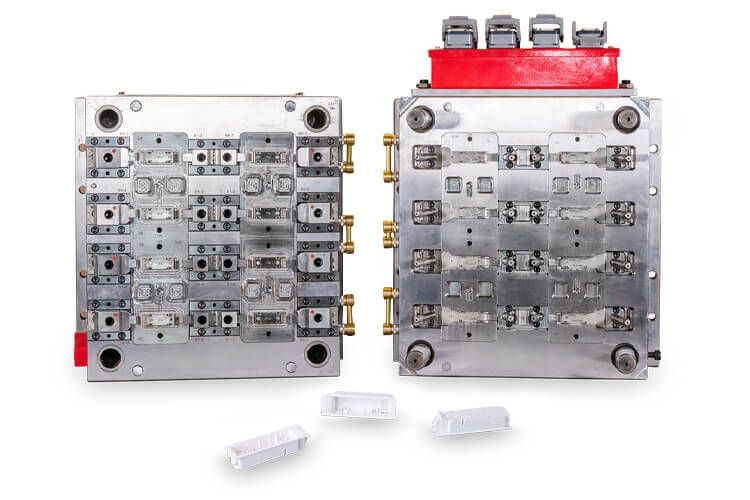

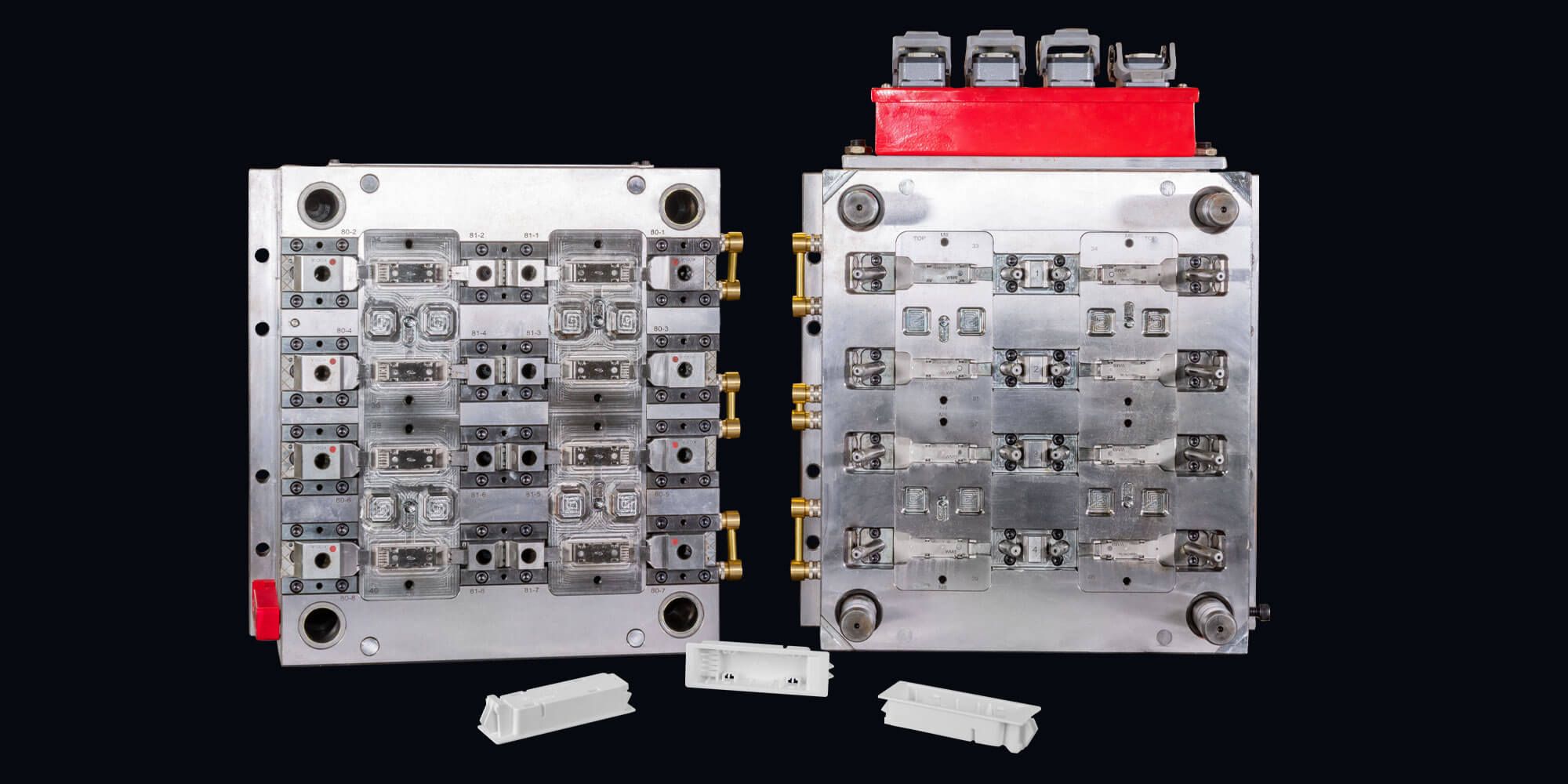

MegaPlast GmbH was founded in 1991 and is your reliable partner for injection molding and mold making.

With competence, experience and willingness to perform, we can cover the entire spectrum of the product development process for our customers individually, from the conception to toolmaking and series production.

On the material side, we process all common thermoplastics in our injection molding production, as well as thermosets and high-performance plastics such as PPS.

MegaPrototyping GmbH & Co. KG

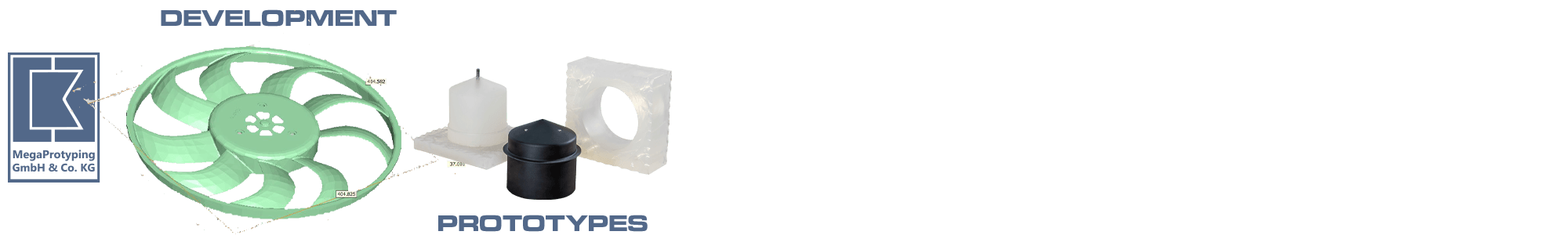

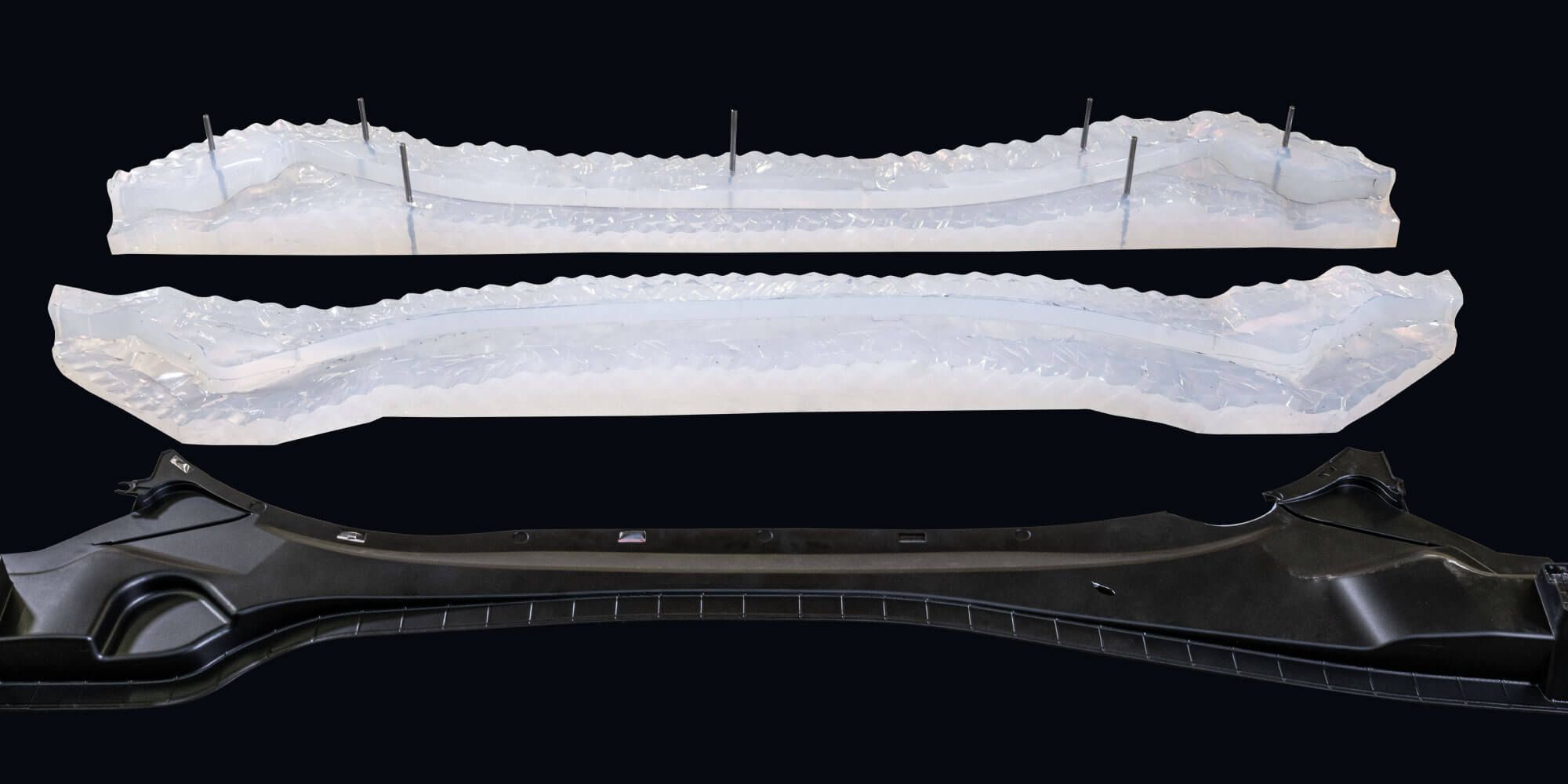

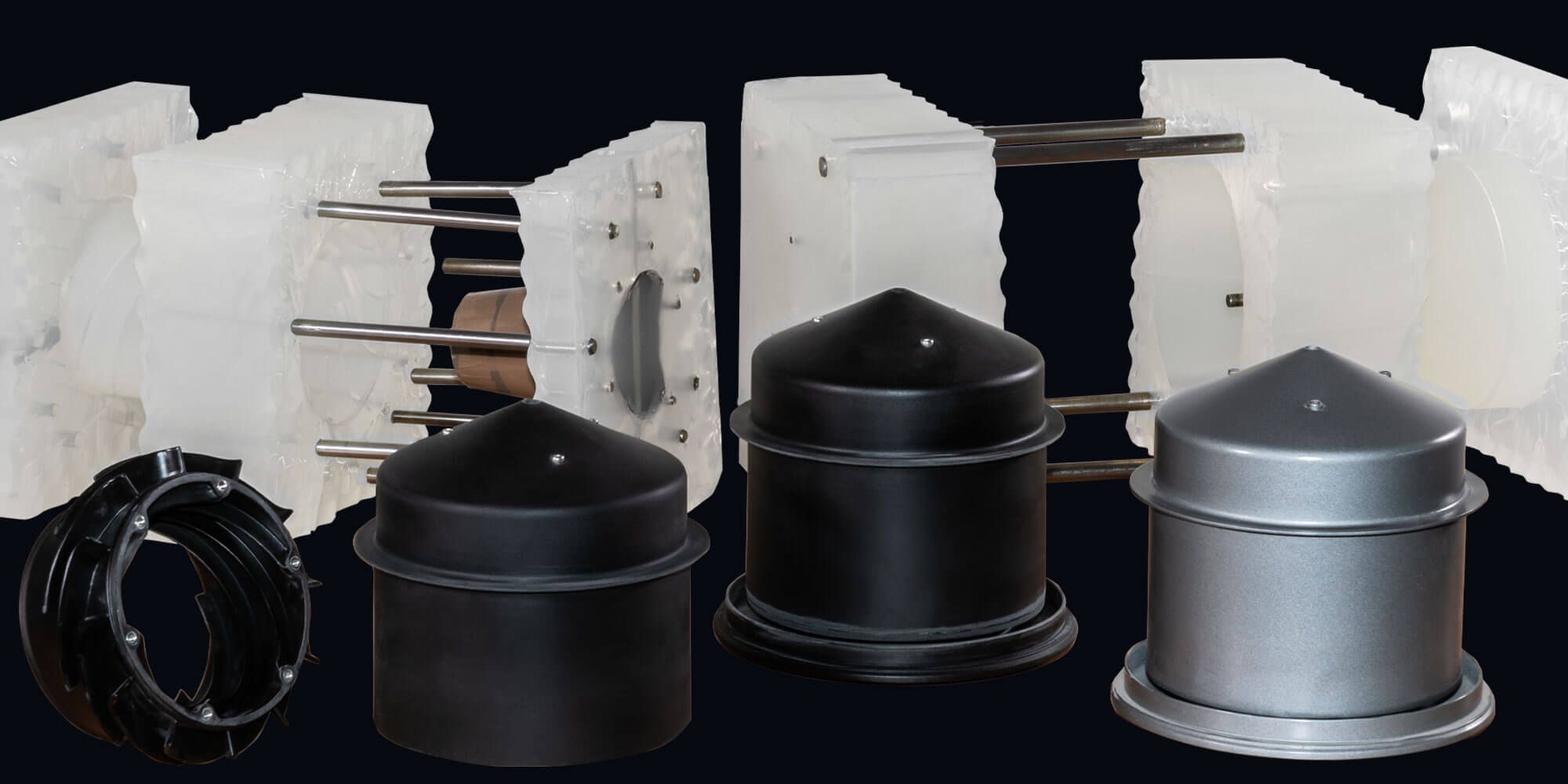

MegaPrototyping GmbH & Co. KG is implememted on the rapid prototyping market since 1991 and supports their customers from a wide variety of areas in development.

In addition to vacuum casting machines from HEK and SLM, our machine park includes 3D printers from Stratasys & Keyence.

In close cooperation with our sister company MegaPlast, we are able to transfer the pre-series projects started in this way to series production in injection molding if desired by the customer.

Our range of services

Our Competences

Our Quality Assurance

We work and act in accordance with DIN ISO 9001: 2015 for the long-term realization of quality goals.

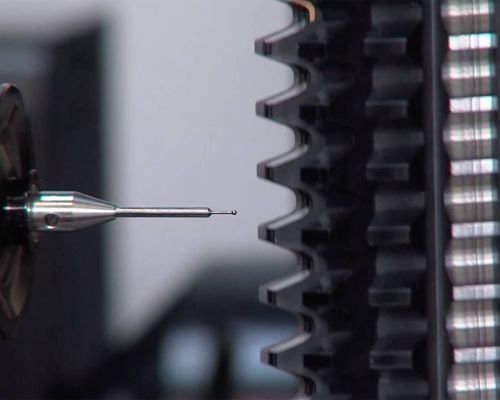

Furthermore, we are able to measure components optically and digitally in 3D at any time with the help of our Werth & Keyence measurement systems.

Even an EMPB preparation according to VDA is no problem.